NC Press Break

Factoy Driectly Price: $45000

As China premier NC Press Brake Machine manufacturers, we incorporate innovative technology and reliable controllers to manufacture top-tier equipment. Our machines are cost effective, hardy, high pericision, low maintance and generate maximum productivity with minimal investment

Standard equlipment:

- (Y and X axes) Controller:Estun E21

- Oil Pump: USA Sunny

- Main Motor: WNM , Siemens

- Linear Guide, Backgauge, Ball Screw Rod: HIWIN

- Grating ruler: Fagor

- Hydraulic System: Bosch Rexroth - Germany

- Tube ConnectorGerman EMB

Optional Accessories

- Mechanical Crowning

- Optical Safety Guard

- Quick Release Clamp

- Temperature control: heating unit / air cooling unit

- Front protection: Light curtain / LASER protection

- Rear Protection: Light Curtain/Full Protection/Semi-protection

Hydrualic NC Press Break WIth EC 21 Controller

Our Hydraulic Press Brake with E21 Controller boast a variety of advantages,

Bending capacity up to 500 tons and 6 meters in length along with digital readouts for stroke control and power back gauge position accuracy all fitted as standard, these reliable machinery are the perfect solution when it comes to maintaining versatility while boosting productivity. For added safety measures side guards and rear electrical interlocks have been incorporated into every machine.making them an ideal cost-effective choice for common prodcution .

Steel frames, torsion bars and hydro-mechanical balancing systems ensure NC press brakes are built for lasting performance. Enjoy years of reliable operation with this sturdy machinery!

Advantages:

- By utilizing the advanced integrated hydraulic system from Bosch Rexroth, Germany, quickly and effortlessly transition between fast-paced and slower bend operations.

- To ensure pinpoint accuracy, the NC E21 system programs both X- and Y-axes to accurately position the inverter.

- outfitted standard with a single-axis backgauge system (X-axis) and bending angle system (Y-axis). For even greater accuracy, opt for V axis compensation functionality to effortlessly bend form complex shapes.

- The design of compensation and mechanical synchronous mechanism increase work piece precision.

- Manually adjustable travel and distance of the back gauge, indicated by a digital meter

- Safety guardrails and electric interlocking devices ensure the safety and stability of the machine

- Precise back gauge travel and distance, digital display to ensure operational accuracy

- Tool holder with wedge adjustment function

- Gooseneck top dies and multi-blade bottom dies to meet the versatility of your bending needs

- Our pre-set, two-speed bending cycle gives you fast approach, slow bending, and fast return for efficient and reliable performance.

- With a front-operated 750mm ballscrew back gauge and digital readout control, you can achieve 0.1mm precision with ease. Two micro-adjustable finger-stops also provide added convenience for accurate positioning.

- Foot switch: normal bend, pause at any stroke point, and release auto return

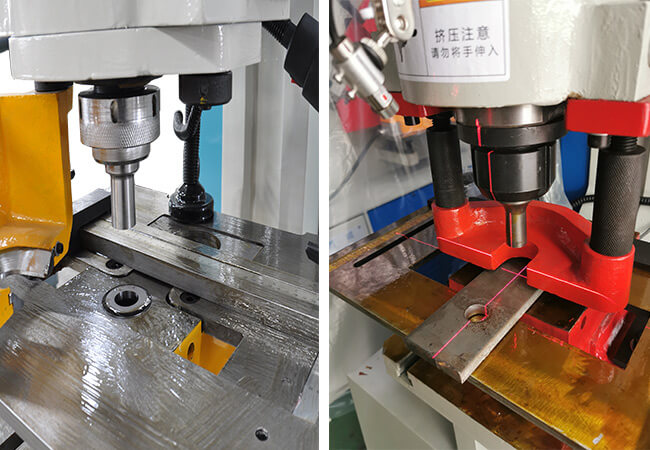

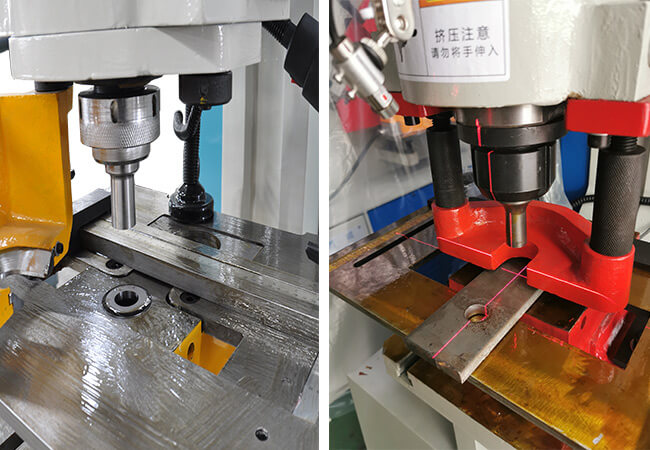

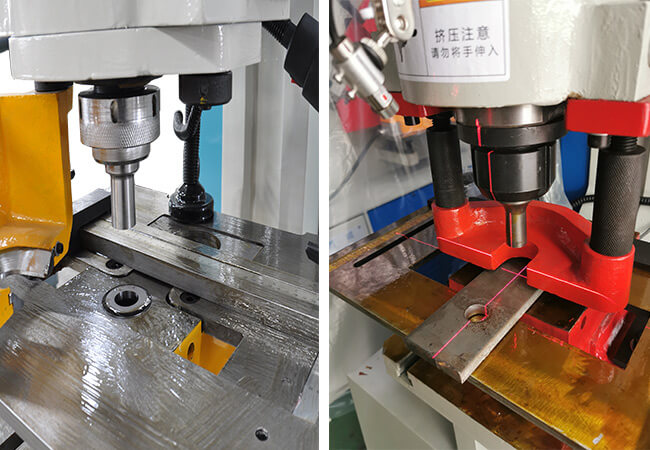

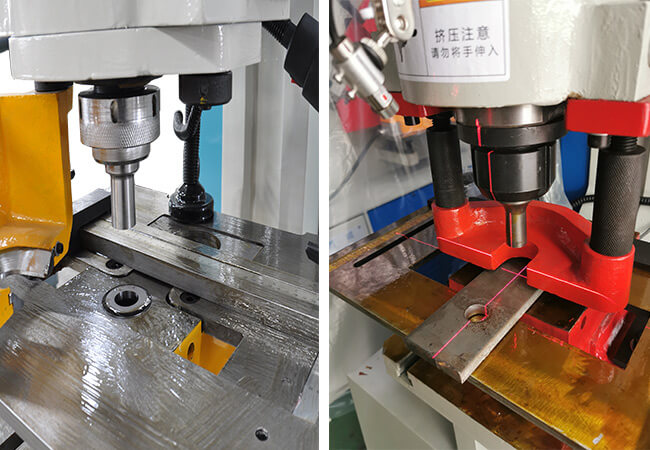

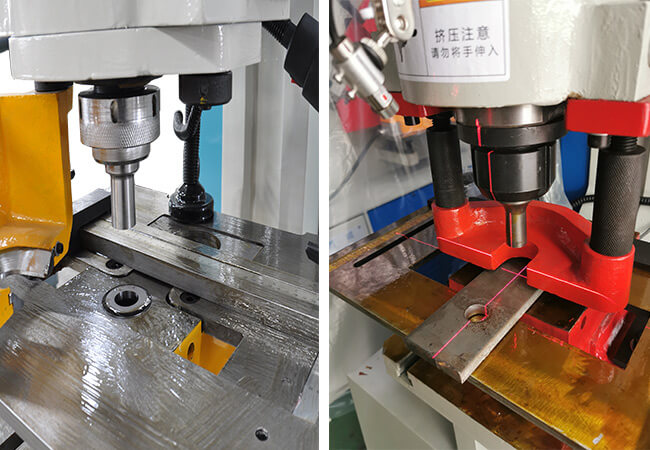

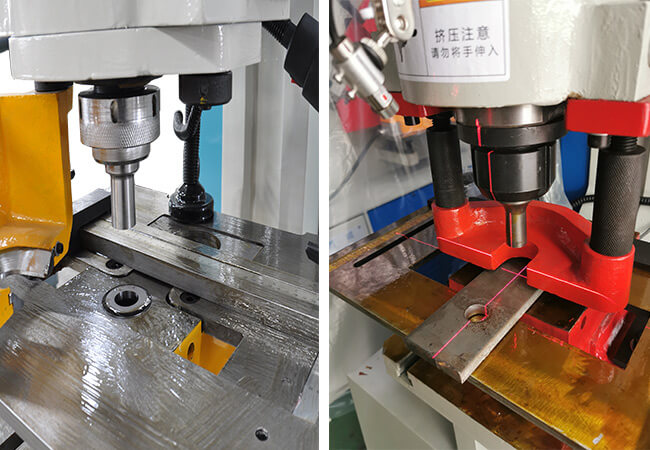

Quick clamps

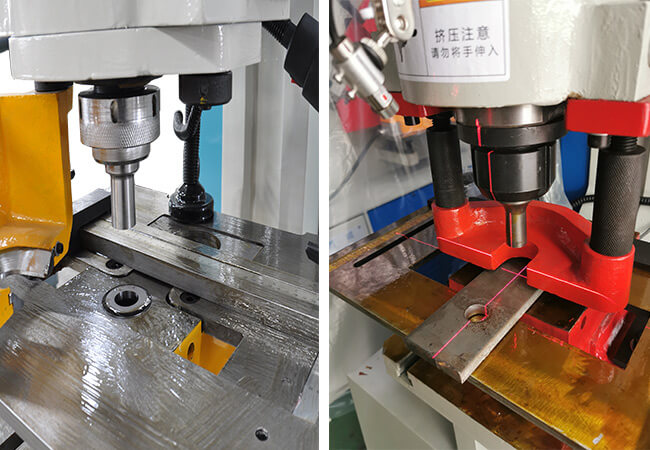

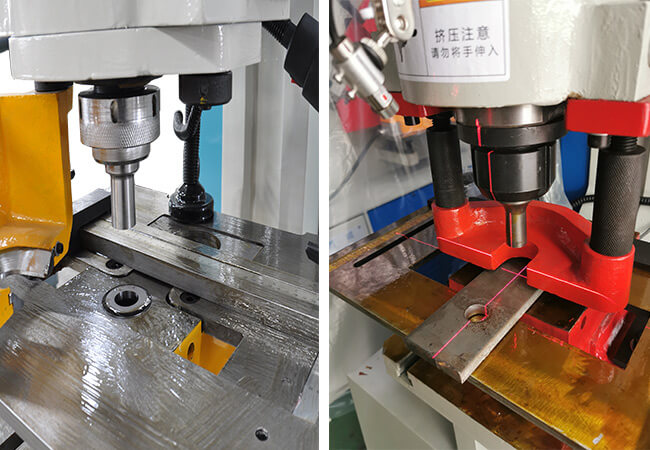

EMB tube

Sunny oil pump

Hydraulic System

schneider electrics

Siemens Motor

South Korea KACON foot switch

Upper Punch (90°)and Multi-V Die

Hydrualic Press Break Peremeters

| Specification | NominalPressure kN |

Length ofworking table mm |

Distance betwwen uprights mm |

Throat depth mm |

Ram stroke mm |

Motorpower kW |

| WC67Y/K-40/2000 | 400 | 2000 | 1800 | 250 | 100 | 4 |

| WC67Y/K-40/2200 | 400 | 2200 | 1800 | 250 | 100 | 4 |

| WC67Y/K-40/2500 | 400 | 2500 | 2000 | 250 | 100 | 4 |

| WC67Y/K-50/2500 | 500 | 2500 | 1900 | 250 | 100 | 4 |

| WC67Y/K-50/3200 | 500 | 3200 | 2600 | 250 | 100 | 4 |

| WC67Y/K-63/2500 | 630 | 2500 | 2020 | 250 | 120 | 5.5 |

| WC67Y/K-63/3200 | 630 | 3200 | 2600 | 250 | 120 | 5.5 |

| WC67Y/K-80/3200 | 800 | 3200 | 2600 | 250 | 120 | 5.5 |

| WC67Y/K-80/4000 | 800 | 4000 | 3200 | 250 | 120 | 5.5 |

| WC67Y/K-100/2500 | 1000 | 2500 | 2000 | 320 | 120 | 7.5 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2600 | 320 | 120 | 7.5 |

| WC67Y/K-100/4000 | 1000 | 4000 | 3200 | 320 | 120 | 7.5 |

| WC67Y/K-100/5000 | 1000 | 5000 | 4000 | 320 | 120 | 7.5 |

| WC67Y/K-125/2500 | 1250 | 2500 | 2000 | 320 | 120 | 7.5 |

| WC67Y/K-125/3200 | 1250 | 3200 | 2600 | 320 | 120 | 7.5 |

| WC67Y/K-125/4000 | 1250 | 4000 | 3200 | 320 | 120 | 7.5 |

| WC67Y/K-125/5000 | 1250 | 5000 | 4000 | 320 | 120 | 7.5 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2600 | 320 | 200 | 11 |

| WC67Y/K-160/4000 | 1600 | 4000 | 3200 | 320 | 200 | 11 |

| WC67Y/K-160/5000 | 1600 | 5000 | 4000 | 320 | 200 | 15 |

| WC67Y/K-160/6000 | 1600 | 6000 | 4800 | 320 | 200 | 15 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2600 | 320 | 200 | 15 |

| WC67Y/K-200/4000 | 2000 | 4000 | 3200 | 320 | 200 | 15 |

| WC67Y/K-200/5000 | 2000 | 5000 | 4000 | 320 | 200 | 15 |

| WC67Y/K-200/6000 | 2000 | 6000 | 4800 | 320 | 200 | 15 |

| WC67Y/K-250/3200 | 2500 | 3200 | 2600 | 400 | 250 | 22 |

| WC67Y/K-250/4000 | 2500 | 4000 | 3200 | 400 | 250 | 22 |

| WC67Y/K-250/5000 | 2500 | 5000 | 4000 | 400 | 250 | 22 |

| WC67Y/K-300/4000 | 3000 | 4000 | 3200 | 400 | 250 | 22 |

| WC67Y/K-300/5000 | 3000 | 5000 | 4000 | 400 | 250 | 22 |

| WC67Y/K-300/6000 | 3000 | 6000 | 4800 | 400 | 250 | 22 |

| WC67Y/K-400/5000 | 4000 | 5000 | 4000 | 400 | 250 | 30 |

| WC67Y/K-400/6000 | 4000 | 6000 | 4800 | 400 | 250 | 37 |

| WC67Y/K-500/6000)) | 5000 | 6000 | 4800 | 400 | 300 | 37 |

| WC67Y/K-500/12000 | 5000 | 12000 | Multi-column | 400 | 300 | 37 |

| WC67Y/K-600/7000 | 6000 | 7000 | 5600 | 400 | 300 | 45 |

| WC67Y/K-700/7000 | 7000 | 7000 | 5600 | 400 | 300 | 45 |

| WC67Y/K-800/6000 | 8000 | 8000 | 5600 | 500 | 400 | 55 |

| WC67Y/K-1000/6000 | 10000 | 6000 | 5600 | 600 | 500 | 75 |

FAQ

The NC Press Brake is a versatile tool that utilizes molds, whether general or specialized, to form cold metal sheets into a variety of geometric cross-sectional shapes. the press brake utilizes a special CNC system designed specifically for this purpose, namely NC (Numeric Controlled) or CNC (Computer Numeric Controlled). as usual, The CNC Price is $10144- $15408 higher than NC, but CNC is a wise investment as it brings more precision and efficiency in use.

NC bending machines are the most cost effective investment for all factories that do not require high precision and productivity.

Currently on the market, there are three types of press break: electric, electro-hydraulic hybrid and hydraulic. Each has superior points

The choice between electric and hydraulic brakes depends on the specific needs of your operation. If you need speed and precision, an electric bending machine is probably the best choice. If you need to bend thicker or heavier workpieces, a hydraulic press break may be a better choice.

如何选择NC 折弯机?在选择数控折弯机时,你应该考虑的因素有:需要折弯的金属板的最大厚度和长度,需要的折弯角度和半径,以及生产量和频率。其他需要考虑的重要因素包括你车间的可用空间和你的预算。

CNC bending machine should be opened every day to clear the machine and the mold on the foreign body, and metal debris. Check whether the mold installation is solid, electrical switches, cable, the fasteners are not normal, there is no loose. Before machine maintenance or wipe the machine, the upper die should be aligned with the lower die and put down the machine off, until the work is completed, if you need to start or other operations, the mode should be selected in manual, and ensure safety. Its maintenance content is as follows:

1、Hydraulic oil circuit

a. Check the oil level of the oil tank every week, such as hydraulic system maintenance should also be checked after the oil level is lower than the oil window should be filled with hydraulic oil;

b. The new machine should be changed after 2000 hours of work, and then every 4000 to 6000 hours of work should be changed after each oil change, and the oil tank should be cleaned;

c. System oil temperature should be between 35 ℃ ~ 60 ℃, shall not exceed 70 ℃, such as too high will lead to deterioration of oil quality and accessories damage.

2、Filter

a. Each time the oil is changed, the filter should be replaced or thoroughly cleaned;

b. machine tools with related alarms or oil quality is not clean and other filter abnormalities, should be replaced;

c. The air filter on the oil tank, every 3 months for inspection and cleaning, the best 1 year to replace.

3, hydraulic components

a. Monthly cleaning of hydraulic components (substrate, valve, motor, pump, tubing, etc.) to prevent dirt from entering the system, no cleaning agents can be used;

b. After one month of use of the new machine, check whether there is deformation at the bend of each oil pipe, if there is any abnormality, it should be replaced, and after two months of use, the connection of all fittings should be tightened.