Menu

From $5800

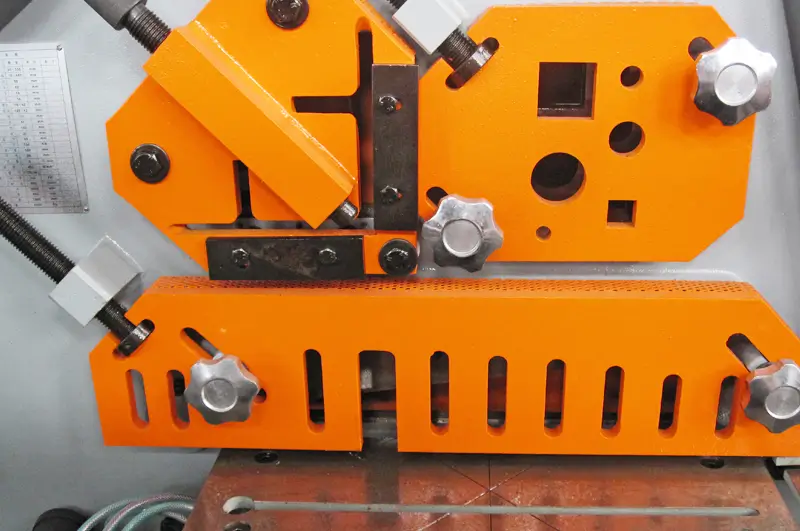

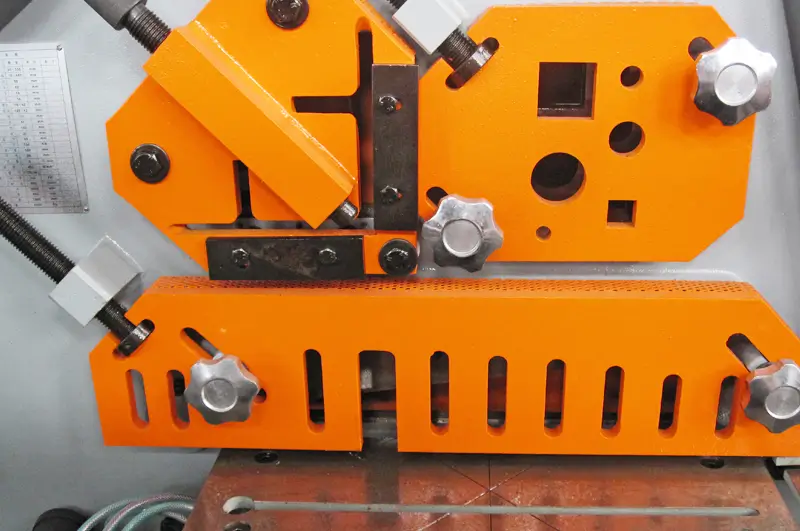

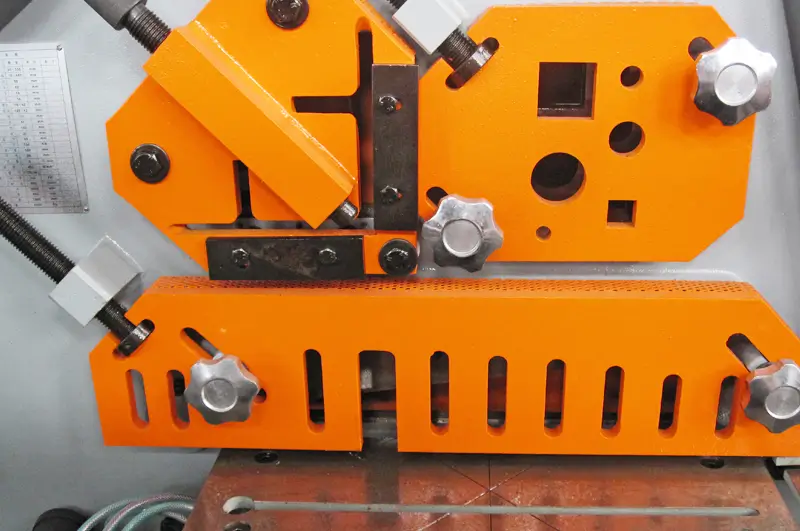

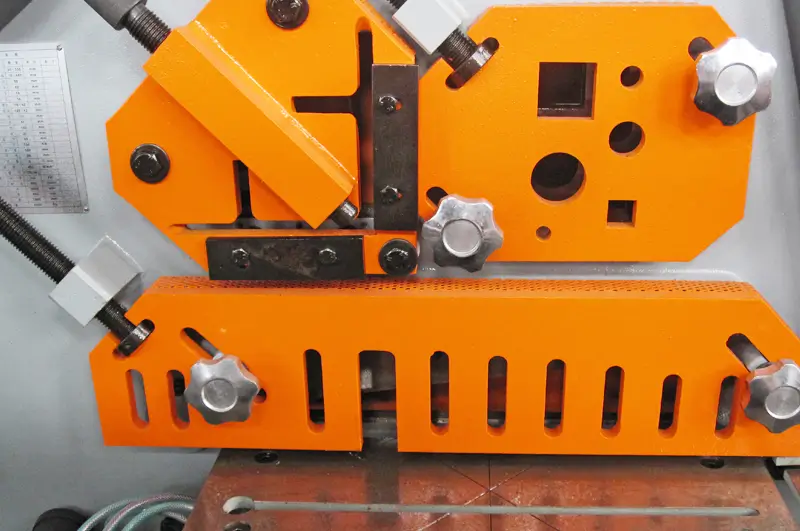

The APEC 90t hydraulic ironworker offers maximum flexibility and versatility for medium to large metalworking companies. Its 90-ton punch brings impressive power to drill (dimensional) holes in 65,000 tensile mild steel – providing unmatched precision and strength for any job you do!

Distinguished from the AIW-60S, this advanced ironworker IW 90 opens up new possibilities in metal processing. With its 90 tons of power and five workstations, it can easily handle difficult tasks – punching and notching square and round metal bars, profile cutting, angle cutting and shearing Its twin pistons allow two operators to work simultaneously, while the adjustable stroke distance can accommodate a wide range of thicknesses。

Operators have the versatility to cope, notch and trim materials of various thicknesses from any angle with ease. The shearing station features quick hold down adjustment for a range of material thicknesses while the punch station boasts an intuitive “dovetail” clamping system that provides fast changeover between punching and small press brake jobs.

1. Free punch and die

2. Maximum punching diameter Φ30, thickness 20mm

3. Precision measuring table, standard equipped with scale and brake

4. Equipped with replacement coupling nut and sleeve

| PUNCHING Model | IW-60S |

| IW-60SD | |

| Punching Force | 60 Ton |

| Punch Capacity S | ø22 x 20 |

| Punch Capacity SD | ø50 x 9 |

| Throat Depth S | 310 |

| Throat Depth SD | 510 |

| Maximum Stroke Length | 100 |

| Cycles / Min. (20mm stroke) | 30 |

| Working Height Up to Die | 1010 |

1. Special upper blade, shear to reduce deformation

2. Four durable cutting edges of the lower blade

3. Support table with guide, biased for accurate positioning

4. Angles can be beveled to different degrees

| FLAT SHEARINGMODEL | IW-60S |

| IW-60SD | |

| Flat Bar Shear S | 350 x 15 |

| Flat Bar Shear SD | 240 x 20 |

| Blade Length | 360 |

| Angle Flange Trim | 100 |

| Working Height | 910 |

1. 45 ° oblique cutting, accurate positioning, small shear deformation

2. Four fixed blades.

3. Mobile blades can flexibly choose the size of the angle corner radius

| ANGLE SHEARINGMODEL | IW-60S |

| IW-60SD | |

| At 90° Shearing | 130 x 130 x 12 |

| At 45° Miter Shearing | 65 x 65 x 8 |

| Working Height | 1115 |

1. 45 ° oblique cutting, accurate positioning, small shear deformation

2. Four fixed blades.

3. Mobile blades can flexibly choose the size of the angle corner radius

| FLAT SHEARINGMODEL | IW-60S |

| IW-60SD | |

| Flat Bar Shear S | 350 x 15 |

| Flat Bar Shear SD | 240 x 20 |

| Blade Length | 360 |

| Angle Flange Trim | 100 |

| Working Height | 910 |

1. One hold-down for various sizes of square bar shearing and round bar shearing.

| BAR SHEARINGMODEL | IW-60S |

| IW-60SD | |

| Round Bar Shear | ø40 |

| Square Bar Shear | 38 x 38 |

| Channel Shear (H x B) | 125 x 65* |

| IBeam Shear (H x B) | 100 |

| Working Height | 1220 |

1. Ideal for notching of flat bars and angles.

| NOTCHING Model | IW-60S |

| IW-60SD | |

| Rectangular Notcher (W x D x T) | 50.8 x 90 x 9 |

| Vee-Notcher | 90 x 90 x 10* |

| (Side x Side x T) | |

| Working Height | 910 |

We not only provide Factory Directly Price, also Four sets of free Round punch die for our new customer, contact now!

Zecco a smart solution for engineering & industry services.

our services

other pages